-40%

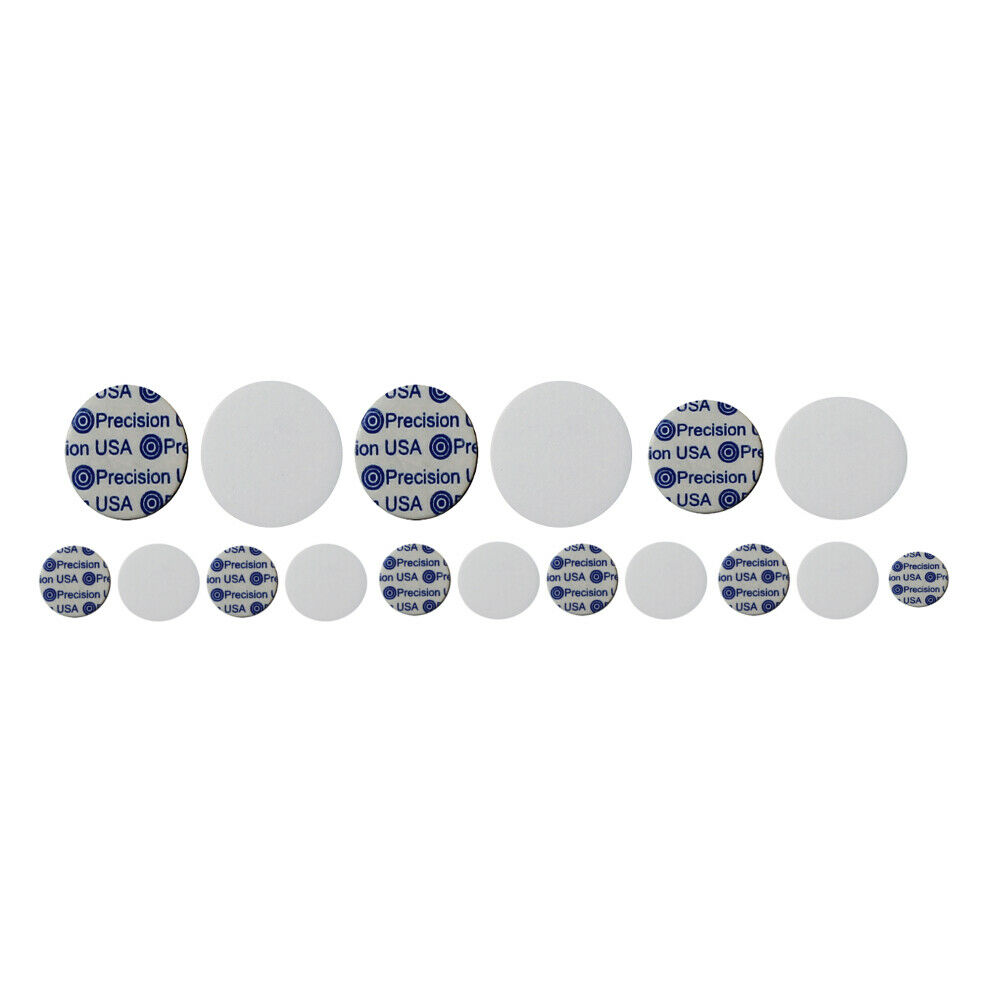

50 SAXOPHONE PADS - 12.5 MM EACH - All our pads are USA Made -

$ 4.2

- Description

- Size Guide

Description

INTERNATIONALSHIPPING

EVERYWHERE !!!

Shop For Band

50 SAXOPHONE PADS - 12.5 MM EACH

These are premium pads made with the finest U.S. made tan kid (goat) skins. They are fully tanned, fully grained, pneumatic and waterproofed. This leather is treated to avoid "stickiness". Backing is 100% woven felt or hardness 65 Rockwell. Harder felt will guarantee a light crease for fast action professional performers.

Full cardboard back.

We are a pad distributor and these are top quality USA made pads.

We have pads for all saxophones.

These pads require pad glue (sold separately).

Purchase Ebay Pad Glue

INSTALLING SAXOPHONE PADS

The MAIN THING to know here is, "YOU CAN DO THIS"

First you will need a good clear work surface to lay out parts. Remember, you will reassemble in reverse order from disassembly.

Remove the keys for pads being replaced. It's probably better to do a section at a time. Be sure to keep keys and screws in order as that will greatly ease the pain of reassembly.

Once you have the keys off, clean the sax.

You can now polish your keys and replace the pads. Never use a wet polish. Use a dry polish cloth or NEVR-DULL polish which is not a liquid.

Remove old pads from the cups by scrapping out the old pad. Clean the cup as much as possible. If you have trouble getting it clean, you can heat the pad cup with a match or lighter to soften the old glue.

Put a glue pellet in the pad cup and apply heat to back of pad cup (you can use a lighter for this). The larger pads will likely use 3 or 4 pellets. Position the pad in the cup and level as much as you can. Adjustments can be made later.(br)

HINT: The glue will continue to melt after the heat is removed. Do not overheat. You may find that depending on your pad cups, one pellet is too much. You can carefully remove unmelted glue with a long pin or needle. Of course be careful, the material is very hot.

Reassemble the saxophone.

Adjust for air leaks by using a match or lighter to heat the back of the pad cup until the glue is softened. Let the pad cup rest lightly against the tone hole. Test for leaks.

This process may take some trial and error, just keep working on it. In some cases (instrument dropped, etc.) you may need to straighten or slightly bend keys to get proper fit.

CAUTION

Never let the flame hit the pad or you will need a new pad.

PATIENCE IS A KEY HERE.

Have fun with it and don't get in a hurry.

THAT'S IT.

INTERNATIONAL

SHIPPING

EVERYWHERE !!!